PVC liners, made from polyvinyl chloride, are a popular choice for swimming pools due to their durability, affordability, and ability to effectively handle pool chemicals and treatments. Unlike plastered or fiberglass pool surfaces, PVC membranes offer unique advantages that make pool maintenance easier and more cost-effective for homeowners. In this article, we’ll look at how PVC coatings interact with common pool chemicals, highlight their advantages, and compare them to other pool coatings.

What are PVC Liners?

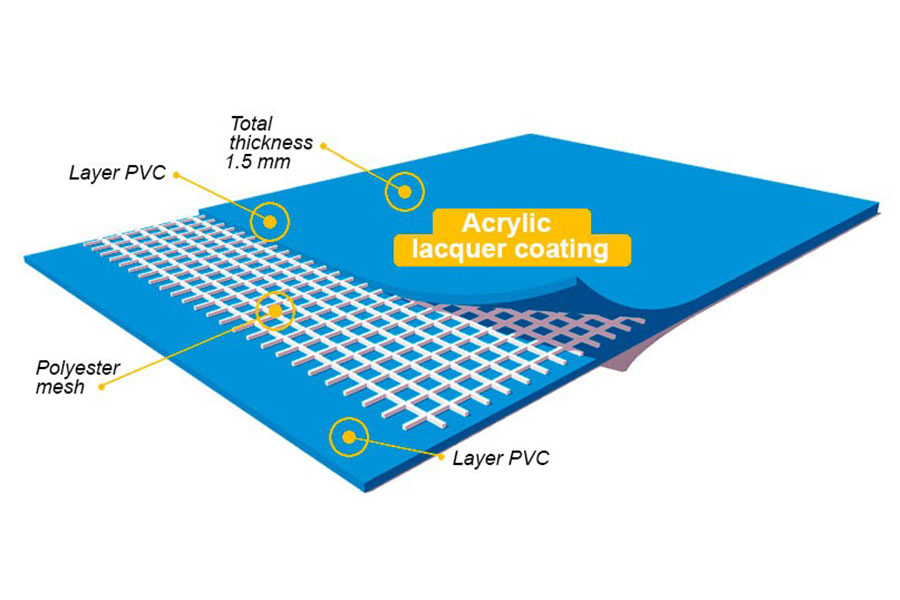

PVC liners are flexible, waterproof membranes that are installed on concrete or other pool substrates. They act as a barrier between water and the pool structure, providing a smooth, non-porous surface. This construction contrasts with all-concrete pools that are painted or plastered, and fiberglass pools that use a pre-molded, gel-coated shell. PVC liners can be replaced. Conventional versions of PVC liners last up to 10 years with proper care. Thick reinforced membranes, such as Cefil 60 mil pool liners, can last over 20 years, making them a practical option for many.

How PVC Liners Handle Pool Chemicals

Pool chemicals such as chlorine, pH adjusters and algaecides are essential to keeping water clean and safe. PVC liners are designed to withstand these treatments, but their effectiveness depends on proper use. Here’s how they handle the major chemicals:

- Chlorine: Used to kill bacteria, chlorine is safe for PVC liners at recommended levels (1-3 parts per million, or ppm). Excessive amounts of chlorine can cause the liner, like other liners, to fade or weaken over time. But this can be prevented with regular water composition testing

- pH Adjusters: Maintaining a pH between 7.2 and 7.6 is very important. A low pH (too acidic) can lead to liner erosion, and a high pH (too basic) can lead to scale formation. PVC liners tolerate these changes well if they are balanced

- Algaecides: These prevent the growth of algae that can stain the liner or make its surface slippery. The smooth surface of a PVC liner resists algae better than plaster or tile, and algaecides enhance this protection without harming the liner

- Shock Treatment: Shock doses of chlorine clear turbid water. PVC membranes do an excellent job of shock treatment if the chemicals are properly diluted and not left concentrated on the surface

With consistent care, PVC liners remain resilient, avoiding the chemical pitting seen in plaster or the gel-coat wear in fiberglass.

PVC Membrane Care Tips

To keep it in great shape, follow these simple steps:

- Test Your Water Regularly: Test chlorine, pH, and alkalinity (80-120 ppm) weekly with a home test kit ($20-50). This will avoid chemical imbalances

- Add Chemicals Gradually: Pour chemicals into the deepest part of the pool with the pump running to distribute them evenly

- Brush Gently: Use a soft brush to clean the membrane surface after treatment to prevent fouling and scratching

- Rinse Equipment: Clean skimmers to avoid corrosive residues

These habits ensure chemicals enhance the pool without damaging the PVC liner.

Advantages of PVC Liners over Other Coatings

PVC liners stand out for their chemical compatibility and overall benefits. Here’s how they compare to stucco and fiberglass:

Chemical Resistance:

- PVC Liners: Non-porous, resists chemical staining and algae adhesion when water balance is maintained

- Plaster: Porous surfaces absorb chemicals resulting in staining, etching, or scaling. Acid washing is often required, increasing costs

- Fiberglass: Gel-coats resist chemicals well but can fade or chalk over time, requiring polishing or re-coating

Easy Maintenance:

- PVC Liners: Smooth surfaces clean quickly with minimal cleaning. Water chemistry balance is key, but this is easier than stucco maintenance

- Plaster: Requires frequent brushing and chemical treatments to eliminate porosity, and periodic replacement of the coating

- Fiberglass: Low maintenance due to non-porous finish, but repairs to gel-coat are trickier and costlier than PVC patches

Cost Effectiveness:

- PVC Liner: Initial cost and replacement is lower than stucco with high maintenance or fiberglass

- Plaster: Expensive to install and maintain, and chemical treatments increase long-term costs

- Fiberglass: Higher initial cost, but less chemical use offsets some costs, but still less “flexible” than PVC membranes

Easy to Repair:

- PVC Membranes: Mechanical tears can be repaired quickly and easily with affordable vinyl kits ($10-$15)

- Plaster: Cracks or chemical damage require professional repairs that can cost thousands

- Fiberglass: Gel-coat repairs are specialized and pricier than PVC patches

In this way, PVC membranes offer a balance of durability and affordability that is hard to beat.

Have Questions?

Talk to our specialist! Just fill out the form, and we’ll give you a call!

Where to Buy a Quality PVC Membrane at an Affordable Price

SAKKO POOL offers a wide range of textures and colors of quality reinforced membrane of the European manufacturer. For example, lately one of the most popular is black pool liner. Our specialists will answer all your questions, assess the condition of the pool, calculate the budget, and help with the choice of the optimal liner.

6 Comments

Jason Carter

Hi! How should the chemicals be diluted?

Konstantin Muraviov

Hi Jason! All chemicals must be diluted in sufficient water before adding them to the pool. A bucket or other suitable container can be used for this purpose. This simple measure will prevent concentrated chemicals from “burning” the pool liner.

Emil Brooks

What chemicals are added to the skimmer?

Konstantin Muraviov

Hi Emil! It is convenient to place so-called long-term chlorine tablets in the skimmer. They serve for water disinfection. Also, if the pool water has a high content of salts of various minerals (copper, manganese and others), special reagents are added to the skimmer to normalize their level.

Nathan Reedok

Can different chemicals be added at the same time?

Konstantin Muraviov

Hi Nathan! Unless the instructions for the chemicals state otherwise, simultaneous addition of different chemicals is possible.