If you’re thinking about adding some fun to your backyard or just interested in the latest advancements in pool technology, let’s talk about ICF Pool Construction and why it’s becoming one of the smartest ways to build a modern swimming pool. These aren’t your grandpa’s traditional setups — this is an efficient, durable, and cost-effective solution for long-term pool ownership.

ICF stands for “insulated concrete forms.” Imagine a pool where the water stays warm without increasing heating bills—that’s the magic of ICF. In this simple guide, we’ll break down how they work, the materials used, their advantages, and even how they compare to other types of pools. Whether you’re a newbie or an experienced swimmer, you’ll understand why ICF could become your best friend in pool ownership matters.

How ICF Blocks Work in Pool Construction

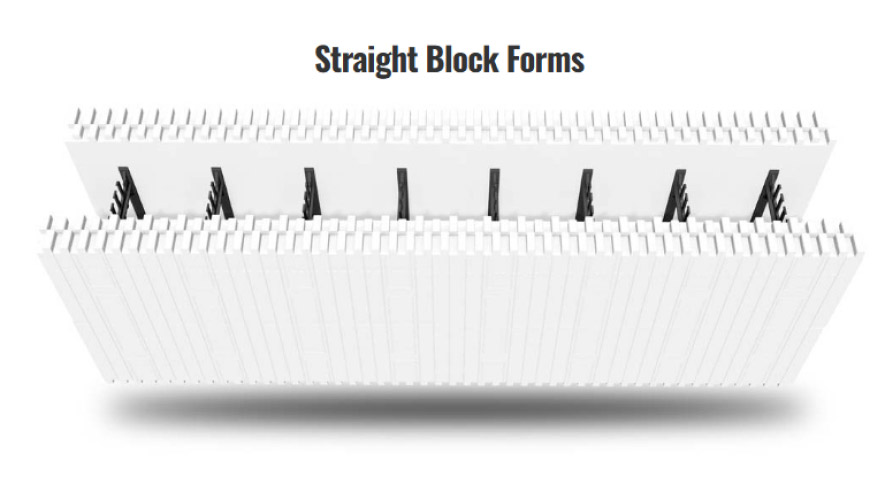

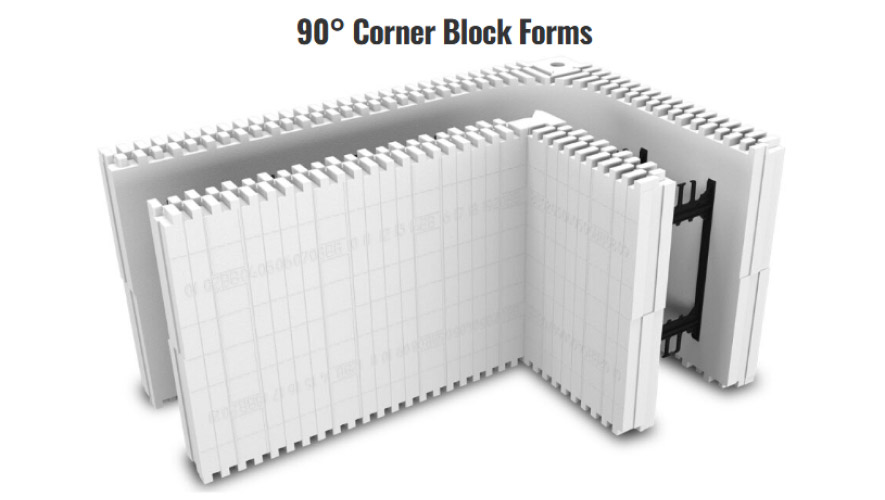

Imagine: building a pool is like stacking giant lightweight bricks, or assembling a huge LEGO set. Construction using ICF blocks starts with excavating the ground for the future pool shell. Then, you can go two ways.

- In the second case, ICF blocks and rebar are installed in such a way that the base (bottom) and walls of the pool are poured with concrete simultaneously. This creates a monolithic structure that, although more complex to install, is stronger. This approach is often recommended by experienced ICF Pool Builder Wellington FL teams for projects requiring maximum durability.

- In the first case, a sturdy concrete base is poured. Then, the most interesting part begins—the foam forms easily connect, forming the walls of your pool. Inside these forms, steel rebar adds strength. Next, concrete is poured, filling the voids and hardening into a sturdy structure. The foam remains in place, serving as permanent thermal insulation. The whole process is faster than you think, often completing in a few weeks rather than months. Plus, it allows for creative shapes, from curved freeforms to sleek swimming zones. No wonder builders love it—less dirt, faster results, and happy homeowners who can start swimming sooner!

Materials Used in ICF Blocks: EPS vs. Polyurethane

ICF blocks are made from two main types of foam: expanded polystyrene (EPS) and polyurethane. Each has its own features and advantages, so let’s compare them in a simple way.

- Expanded Polystyrene (EPS): This is the lightest material, made from tiny granules expanded with steam. It’s affordable, resistant to mold, and easy to shape. Properties include good thermal insulation (R insulation coefficient about 4-5 per inch) and fire-retardant additives. Advantages: Affordable for most projects, recyclable, and very lightweight—ideal for DIY work. Externally, it often has a white or gray color with a granule-like texture.

- Polyurethane: Denser and high-quality. It has top-notch insulation properties (R coefficient 6-7 per inch) and excellent moisture impermeability. Advantages: Better suited for humid climates, stronger structure, and better sound insulation. Disadvantages? Slightly more expensive. Visually, it’s smoother, usually yellow or pink, with a uniform texture.

Both materials are fire-resistant and eco-friendly, but choose EPS for cost savings, and polyurethane for added strength in humid climates.

Key Advantages of ICF Block Pools

Why choose ICF blocks? Here’s why they’re so popular:

- Energy Savings: Built-in insulation maintains stable water temperature, reducing heating costs by up to 80%. That’s a longer swimming season without shocking bills!

- Quick Construction: Snap-together forms mean your pool is ready faster, minimizing inconvenience on the site and labor costs.

- Incredible Durability: The concrete core withstands ground shifts, freezing, and bad weather, lasting over 30 years.

- Environmental Benefits: Reduced energy consumption lowers your carbon footprint, and materials are often recyclable—great for those who care about the environment.

- Quiet Comfort: Foam dampens noise, creating a quiet oasis away from street sounds.

Comparing ICF Block Pools to Other Types

Now let’s see how ICF blocks compare to classic options. Traditional pools from gunite (sprayed concrete) offer boundless customization possibilities, but their construction takes a lot of time, and they consume a lot of energy without insulation. ICF pools outperform them in efficiency and speed, with similar strength but better temperature control—advantage ICF in long-term cost savings.

Fiberglass pools install quickly, inexpensive initially, but limited in shape choices and prone to cracking with ground shifts. ICF offers greater design flexibility and superior insulation, making them more durable and adaptable—advantage ICF in durability.

Pools with vinyl lining 20–27 mil are a budget option, but the lining wears out every 5–7 years and requires replacement. ICF’s permanent structure means lower maintenance costs, as well as energy efficiency advantages—clear advantage ICF in the long term.

Overall, ICF outperforms other options if you need efficiency and durability; traditional pools suit super-custom or super-cheap projects.

Have Questions?

Talk to our specialist! Just fill out the form, and we’ll give you a call!

Finishing Touches: The Best Lining for ICF Pools

In conclusion, use a thick reinforced PVC membrane for your insulated concrete form pool, such as Cefil 60 mil pool liner. This will provide waterproofing, flexibility with movement, and added puncture resistance, ensuring your pool remains in perfect condition for 25–30 years.

In the end, ICF block pools are an eco-friendly and forward-thinking choice. Made from expanded polystyrene (EPS) or polyurethane, they provide advantages like savings and strength, excellent insulation, outperforming other options.

Ready to dive in? Chat with a professional—SAKKO POOL, get answers to all questions. Your ideal pool awaits you!

FAQ

Other articles on this topic

Common Pool Liner Problems: Insights from Reddit Communities

ICF Blocks Compared: Stronghold vs. BuildBlock – Which One Wins?

Common Pool Liner Mistakes to Avoid: Lessons from Real Renovation Projects

Insulated Swimming Pool Benefits: Energy Efficiency and Year-Round Use

ICF Pools vs Traditional Pool Construction: Which Method is Better?

Everything You Need to Know About ICF Pools: In-Depth Guide by Sakko Pool

Understanding ASR: The “Concrete Cancer” Threatening Swimming Pools