Building an in-ground pool is a significant investment that can enhance your backyard and provide years of enjoyment. However, given the variety of construction methods available, choosing the right option depends on factors such as individual requirements, durability, timing, and budget. This article compares two popular options: gunite pools and ICF pools lined with thick reinforced PVC membrane.

What is a Gunite Pool and ICF Blocks?

Shotcrete (gunite) and ICF blocks are used in the construction of the pool basin. This is the frame onto which the cladding will subsequently be installed. How do they differ?

Gunite Pool: A gunite pool is a type of in-ground concrete pool in which a dry mixture of cement, sand, and aggregates is sprayed under high pressure onto a steel reinforcement frame using a spray machine. Water is added through the nozzle during application, ensuring precise control and a strong bond. This method creates a durable and easily customizable shell that is popular due to its flexibility in shape and size. The concrete shell is then covered with a facing material, such as plaster or tile.

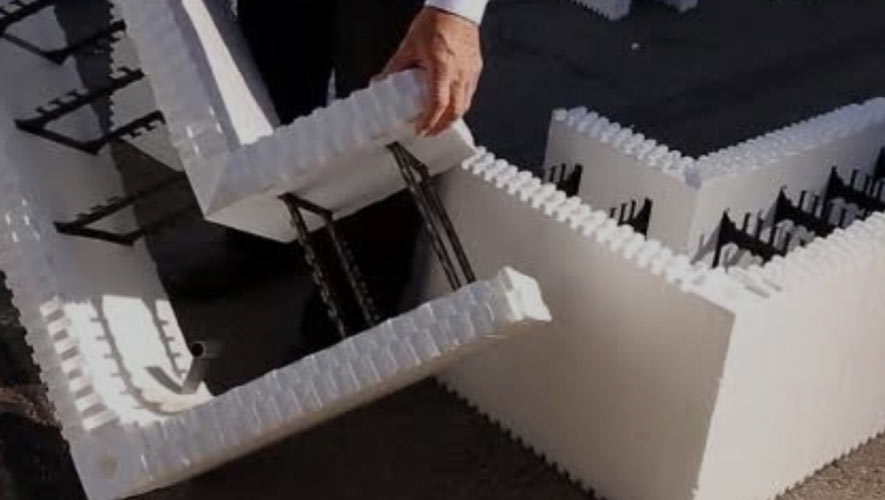

ICF Block Pools: Insulated concrete forms (ICFs) — hollow blocks made of expanded polystyrene — are used to construct the pool basin. These blocks are stacked on top of each other like LEGO bricks, reinforced with steel reinforcement bars, and filled with concrete. Once the concrete has hardened, these blocks remain in place, providing good thermal insulation.A thick reinforced PVC membrane, such as Cefil 60 mil pool liner, is used as a lining. This combination of ICF blocks and PVC membrane further improves the thermal insulation properties, which allows for significant savings on heating the pool water.

Stages of Construction

Both types of pools follow the same general process: design, excavation, construction, finishing, and equipment installation, but their methods differ, which affects their complexity and efficiency. If you need consulting for swimming pool building in Wellington, our team can explain each stage in detail.

- Gunite Pools:

- Excavation: Excavation of a pool-shaped pit using heavy equipment; wide range of options for adaptation to individual requirements for unique projects (1–2 weeks).

- Reinforcement and Plumbing: Installation of steel reinforcement cage and water pipes for water circulation and filtration (1–2 weeks).

- Gunite Application: Applying shotcrete in layers to the reinforcement cage, shaping the pool (1 week).

- Finishing: Plaster, tiles, or other finishing coatings may only be applied after the concrete has completely set; installation of decking, and equipment such as pumps and filters (2–4 weeks).

Important! Concrete requires at least 28 days to cure. Rainy weather may increase this time. Also, before using the pool, it is necessary to balance the chemical composition of the water (1–2 weeks).

- ICF Block Pools with PVC Membrane:

- Excavation: Excavation of a pool-shaped foundation pit (up to 1 week).

- Pool frame assembly: Laying ICF blocks to form walls; installing reinforcement in walls and floor (up to 1 week).

- Concrete Pour: Filling the blocks with concrete (1 day).

- Installation of PVC membrane: Depending on the shape and size of the pool, installing the membrane can take anywhere from a few days to 2–3 weeks. Installation is carried out by thermally welding PVC membrane sheets cut to the shape of the pool. At the final stage, liquid PVC is applied to the seams to ensure absolute waterproofing.

- Filling the pool: One day after installing the membrane (this time is required for the liquid PVC applied to the seams to set), the pool can be filled with water and the chemical composition balanced (1–2 days).

Time Required for Construction

The time required depends on the size of the pool (e.g., 15 x 30 feet), site conditions, and weather conditions, but typical time requirements are as follows:

- Gunite Pools: A total of 8–12 weeks. Earthworks and reinforcement take 2–4 weeks, shotcrete spraying takes 1 week, finishing takes 2–4 weeks, and curing/testing takes 4 weeks. The curing period delays readiness for swimming, as the concrete needs time to fully harden (28 days).

- ICF Block Pools with PVC Membrane: Only 4–6 weeks. Earthworks take 1–2 weeks, block assembly takes 1 week, concrete pouring takes 1 day, membrane installation takes 1–3 days, finishing/testing takes 1–2 days. The absence of the need to remove formwork and wait for the concrete to cure speeds up the process by 30–50% compared to gunite.

Cost of Construction and Maintenance

Costs vary depending on the region, pool size, and pool features. Calculations are based on a standard 15 x 30 foot pool. Maintenance includes annual cleaning, chemical, and repair costs.

- Gunite Pools:

- Construction Cost: $80,000–$100,000 and above. The high cost is due to the labor-intensive spraying and application of special finishing materials such as plaster ($8,000–$10,000) or tile ($15,000–$30,000).

- Maintenance Cost: $1,000–$2,500 per year. Porous surfaces (such as plaster) require frequent acid washing, brushing, and chemical balancing to prevent algae and staining. Resurfacing every 5–10 years costs $10,000–$20,000. Uninsulated shells increase water heating costs (up to $1,000 per year).

- Overall: High initial and ongoing costs; suitable for individual projects, but over time 20–30% more expensive than alternative options.

- ICF Block Pools with PVC Membrane:

- Construction Cost: $60,000–$90,000. ICF blocks reduce labor costs (installation is 20–30% faster). PVC membrane ($6,000–$10,000) is more economical than tiles; overall costs are lower thanks to quick installation.

- Maintenance Cost: $500–1,000 per year. Non-porous PVC membrane (e.g., Cefil 60 mil) is resistant to algae and stain formation, saving 15–20% on chemicals. The thermal insulation properties of ICF blocks and PVC membranes reduce heating costs by 50–70% (savings of $500–700 per year). Replacing the membrane every 20–30 years costs $6,000–10,000.

- Overall: Lower initial and long-term costs; high efficiency: savings of 20–40% compared to shotcrete (gunite) over a decade.

Pros and Cons Comparison

- Gunite Pools:

- Pros: Unlimited choice of shape and size, durable body (over 50 years).

- Cons: Long construction times (8–12 weeks), high initial costs (US$80,000–100,000) and operating costs (US$1,000–2,500 per year), energy consumption without insulation.

- ICF Block Pools with PVC Membrane:

- Pros: Faster construction (4–6 weeks), energy efficiency (50–70% less heat loss), easy maintenance of PVC membrane (20–30 years), cost-effectiveness (US$60,000–90,000), possibility of creating custom colors and textures that imitate tile and natural stone.

- Cons: Less flexible for building pools with complex, non-standard shapes.

Have Questions?

Talk to our specialist! Just fill out the form, and we’ll give you a call!

Conclusion

Gunite pools are the ideal choice for homeowners seeking a premium, custom design, but the lengthy construction time (8–12 weeks) and high cost ($80,000–$100,000 plus $1,000–$2,500 per year for maintenance) make them a more expensive investment.

ICF block pools with a thick reinforced PVC membrane are a faster (4–6 weeks), more affordable ($60,000–$90,000) and energy-efficient alternative with lower maintenance costs ($500–$1,000 per year), ideal for budget-conscious and environmentally conscious homeowners.For questions regarding the purchase of high-quality thick reinforced PVC membranes, please contact SAKKO POOL, the official representative of European manufacturer Cefil in the United States. Our specialists will help you choose the best option that will ensure refined style, efficiency, and durability for many years to come.

FAQ

Other articles on this topic

Common Pool Liner Problems: Insights from Reddit Communities

ICF Blocks Compared: Stronghold vs. BuildBlock – Which One Wins?

Common Pool Liner Mistakes to Avoid: Lessons from Real Renovation Projects

Insulated Swimming Pool Benefits: Energy Efficiency and Year-Round Use

ICF Pools vs Traditional Pool Construction: Which Method is Better?

Everything You Need to Know About ICF Pools: In-Depth Guide by Sakko Pool