Swimming pools have long been a symbol of relaxation and luxury in backyards across America, offering a refreshing escape from everyday stress. But traditional pool construction comes with labor-intensive processes and high costs. ICF pools come to the rescue—an innovative approach that’s changing the game for homeowners and builders alike. What is an ICF pool? Short for Insulated Concrete Forms (insulated concrete blocks), these pools use foam blocks filled with concrete to create energy-efficient and durable structures.

An ICF pool combines the strength of concrete with superior thermal insulation, making it ideal for various climates. Whether you’re building a pool for the first time or upgrading an old one, understanding ICF pools will help you make more informed decisions. Homeowners working with an experienced pool builder Wellington often choose ICF technology for its durability, speed of installation, and long-term energy savings. This method not only speeds up construction but also reduces electricity bills by maintaining stable water temperature. Amid rising material prices and environmental concerns, ICF pools stand out for their eco-friendliness and longevity. In this article, we’ll cover the basics, benefits, construction stages, and why they’re the best choice today. If you’re interested in modern pool construction technologies, read on to learn how ICF can turn your outdoor space into a year-round paradise.

The Basics of ICF Pools

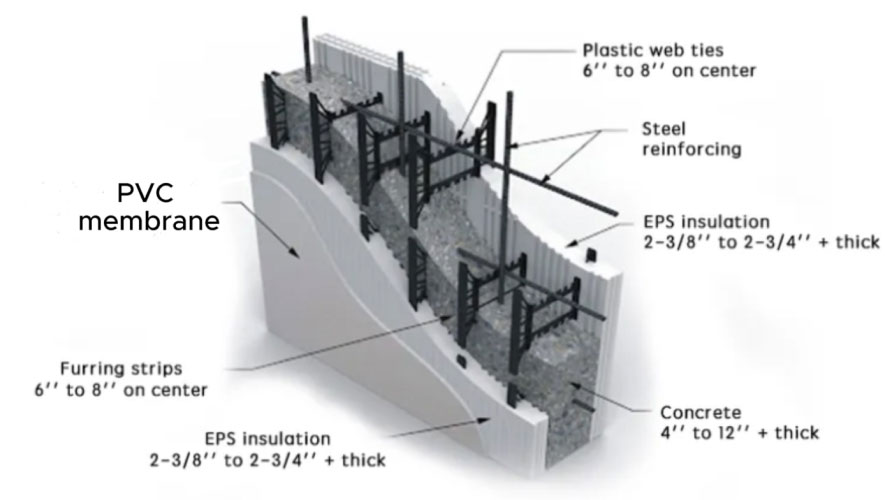

ICF blocks are primarily made from fire-resistant expanded polystyrene (EPS). Despite their large size, they are very lightweight, and one person can stack these blocks.

These blocks connect together like giant Lego bricks. These forms are reinforced with steel rebar and then filled with concrete, creating a sturdy shell. After the concrete hardens, these blocks remain in place, providing built-in insulation on all sides. This design is suitable not only for homes; it’s ideal for public or commercial pools, both above-ground and in-ground. Unlike traditional concrete pools that use shotcrete or sprayed concrete over rebar, ICF pools provide superior thermal insulation properties. The insulation helps maintain water temperature, reducing heating costs by up to 80%. This makes them especially attractive in various climates where energy efficiency is key.

ICF Key Benefits for Homeowners

Foam concrete pools (ICF) have several advantages:

- Energy Savings: The insulating foam (expanded polystyrene) minimizes heat loss, keeping the pool warmer longer and significantly reducing utility bills—ideal for extending the swimming season.

- Faster Construction: The forms assemble quickly, often cutting construction time by several weeks compared to traditional methods.

- Durability and Strength: The reinforced concrete core withstands ground shifts and weather conditions, outperforming other designs in longevity and requiring less maintenance.

- Eco-Friendliness: Lower energy consumption means a smaller carbon footprint, and the materials are recyclable.

For those living in colder regions, ICF block pools can even support heating systems without a sharp increase in costs.

ICF Construction Process

Building an ICF block pool starts with excavating the site and preparing the pit. The pool shell can be created in two ways:

- Monolithic (mono-pour): This method involves simultaneously pouring concrete for the pool bottom and its walls (ICF). This creates a very strong structure.

- Simple (conditional name): First, the concrete base (pool bottom) is poured. Then, walls are stacked from foam concrete forms (ICF), and rebar is inserted inside for strength. Concrete is pumped in, and after hardening, the pool is ready for finishing work such as plumbing, lighting, and lining.

Total construction time? Often just a 5-8 weeks.

Choosing the Right Lining

To maximize the potential of an ICF block pool, the lining is important. The best lining for such pools is a thick reinforced PVC membrane with a thickness of 60 mil, such as Cefil 60 mil pool liner. This durable material reliably seals the structure, flexes with any movement, and is resistant to punctures, ensuring the longevity of your investment. It installs quickly into the pool shell. In addition, the thick reinforced PVC membrane has such advantages:

- Lifespan of 25–30 years.

- Resistant to stains and algae growth.

- Soft surface with anti-slip properties reduces the risk of injury and falls.

- Easy maintenance.

- Low operating costs.

- Wide selection of colors and patterns.

Why Consider an ICF Pool?

Foam concrete pools combine innovation and practicality, offering comfort, savings, and durability. If you’re planning a pool that will stand the test of time, this could be your solution. For consultations on construction or lining (renovation) of an old pool, contact SAKKO POOL to find out if it fits your space—your future self (and your wallet) will thank you!

Have Questions?

Talk to our specialist! Just fill out the form, and we’ll give you a call!

FAQ

Other articles on this topic

Common Pool Liner Problems: Insights from Reddit Communities

ICF Blocks Compared: Stronghold vs. BuildBlock – Which One Wins?

Common Pool Liner Mistakes to Avoid: Lessons from Real Renovation Projects

Insulated Swimming Pool Benefits: Energy Efficiency and Year-Round Use

ICF Pools vs Traditional Pool Construction: Which Method is Better?

Understanding ASR: The “Concrete Cancer” Threatening Swimming Pools